| |

500W HiPIMS Power Supply for Magnetron Sputtering / PVD

The Modular, Research-Grade HiPIMS Power Solution for Uncompromising Precision and Integration.

Engineered for the forefront of thin-film research and high-end system integration, Plasma Technology Limited PTL Advanced HiPIMS Power Supply delivers unparalleled control over plasma ionization and deposition dynamics. With a range of power options and robust industrial features, it is the ideal core component for pioneering research and building next-generation PVD systems.

Designed for Your Specific Needs:

- For Researchers & Academics: Probe the fundamentals of plasma physics and pioneer novel film architectures. Our system provides the parameter space and diagnostic tools to precisely control ion energy, flux, and ratio, enabling groundbreaking published results.

- For R&D Institutes: Bridge the gap between lab-scale innovation and industrial application. Develop robust, repeatable processes for advanced materials with exceptional stability and control.

- For PVD System Manufacturers: Differentiate your product line with integrated, state-of-the-art HiPIMS technology. A compact form factor, standard communication protocols, and easy syncing make integration seamless, offering your customers a definitive performance advantage.

Key Technological Advantages:

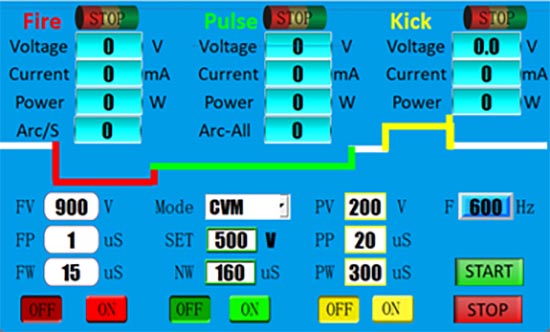

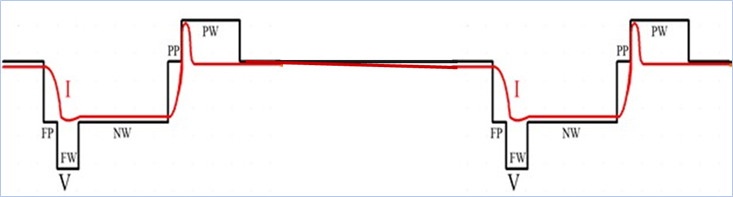

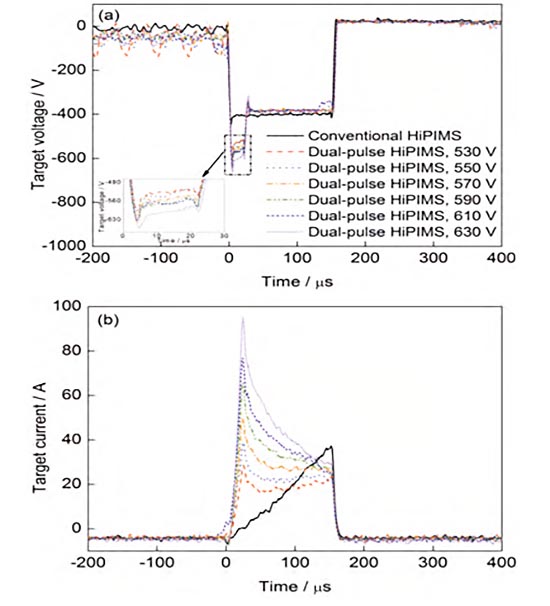

The core of our HiPIMS power supply is a sophisticated triple-pulse architecture, providing independent control over each phase of the plasma discharge - a significant leap beyond standard HiPIMS.

- Independent Fire Pulse (Ignition): Ensures reliable and instantaneous plasma breakdown, guaranteeing process repeatability.

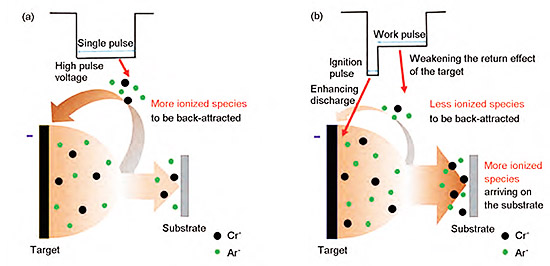

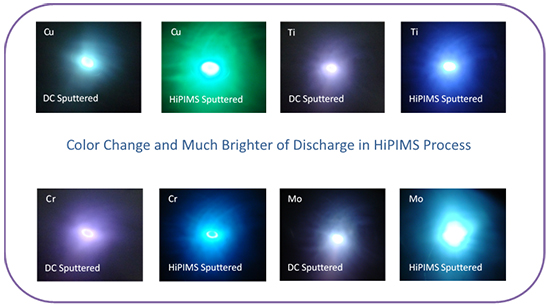

- Independent High-Power ImPulse (Ionization): Generates an extremely high plasma density, achieving ionization fractions exceeding 90% for most metals for fully dense, defect-free films.

- Independent Positive Kick Pulse (Deposition Enhancement): Actively mitigates the deposition rate limitation traditionally associated with HiPIMS, maximizing throughput without compromising quality.

Unmatched Control & Integration Features:

- Scalable Power for Any Application: Choose from 500W, 1kW, or 2kW output models to perfectly match your specific research needs or target size, from compact 2-inch targets up to 4-inch and larger rectangular or circular configurations.

- Precision Parameterization:

- Wide Operating Window: 100A peak current, user-selectable frequency (20 Hz - 10 kHz), and independently adjustable pulse for each pulse (Fire: 400-1.8kV, 1-100us, ImPulse: 0-1kV, 10-300us, Kick: 0-400V, 1-300us).

- Full Phase Shift Control: Precisely manipulate the temporal relationship between all three pulses to independently optimize ignition, ionization, and deposition phases for any target material.

- Comprehensive Process Diagnostics:

- Real-Time Voltage & Current Monitoring: Essential for process development, optimization, and reproducibility. Monitor key metrics directly for unparalleled process transparency.

- Unmatched Process Stability & Arc Management: Ensure flawless film quality and protect your investment with our advanced arc handling system.

- Ultra-Fast Arc Detection & Suppression: Minimizes defects caused by micro-arcs by reacting in nanoseconds.

- Three-Stage Arc Protection: Configurable levels allow for precise management from gentle suppression to hard shutdown, safeguarding both the power supply and your valuable deposition target.

- Seamless Automation & Integration:

- RS485 Modbus Communication: Standard industrial protocol allows for full remote control, data logging, and seamless integration into automated cluster tools or custom software environments. Perfect for unmanned operation and Industry 4.0 readiness.

- Master/Slave Configuration: Synchronize multiple units for dual-cathode co-sputtering or precisely synchronize with a substrate bias power supply.

- Rack-Mountable, Compact Design: Engineered for space-efficient labs and systems. With a streamlined 4U (175mm) height and standard 19-inch (480mm) rack width, it integrates neatly into any existing setup, saving valuable bench or cabinet space.

Technical Specifications Summary:

|

Feature |

Specification |

|

Model |

HiPIMS-100A-0K |

|

Output Power |

500W |

|

Target Compatibility |

2-inch to 3-inch+ (Circular & Rectangular) |

|

Peak Current |

Up to 100A |

|

Pulse Frequency |

20 Hz - 10 kHz (User-Selectable) |

|

Pulse Control |

Independent for Fire (400-1.8kV, 1-100us), ImPulse (0-1kV, 10-300us), and Kick pulse (0-400V, 1-300us) |

|

Phase Shift |

Full control between all pulses |

|

Arc Management |

Fast Detection, 3-Level Programmable Protection |

|

Control |

Touch-Screen Interface, Real-Time V/I Monitoring |

|

Communications |

RS485 with Standard Modbus Protocol |

|

Cooling |

Forced Air |

|

Cabinet |

4U Rack-Mount (175mm H x 500mm D x 480mm W) |

|

Input Power |

AC220V, 50Hz |

Call to Action:

Equip your lab with the precise power and industrial reliability your research demands. Integrate a superior, future-proof capability into your PVD systems.

Contact our technical team today for:

- Detailed specification sheets for each power model.

- Application notes for your specific target material.

- A consultation on integration and automation via Modbus.

Need help?

Contact an Applications Specialist by sending an Email to PTL or call 852-98814818.

For other related products:

1000W HiPIMS Power Supply

2000W HiPIMS Power Supply

|