| |

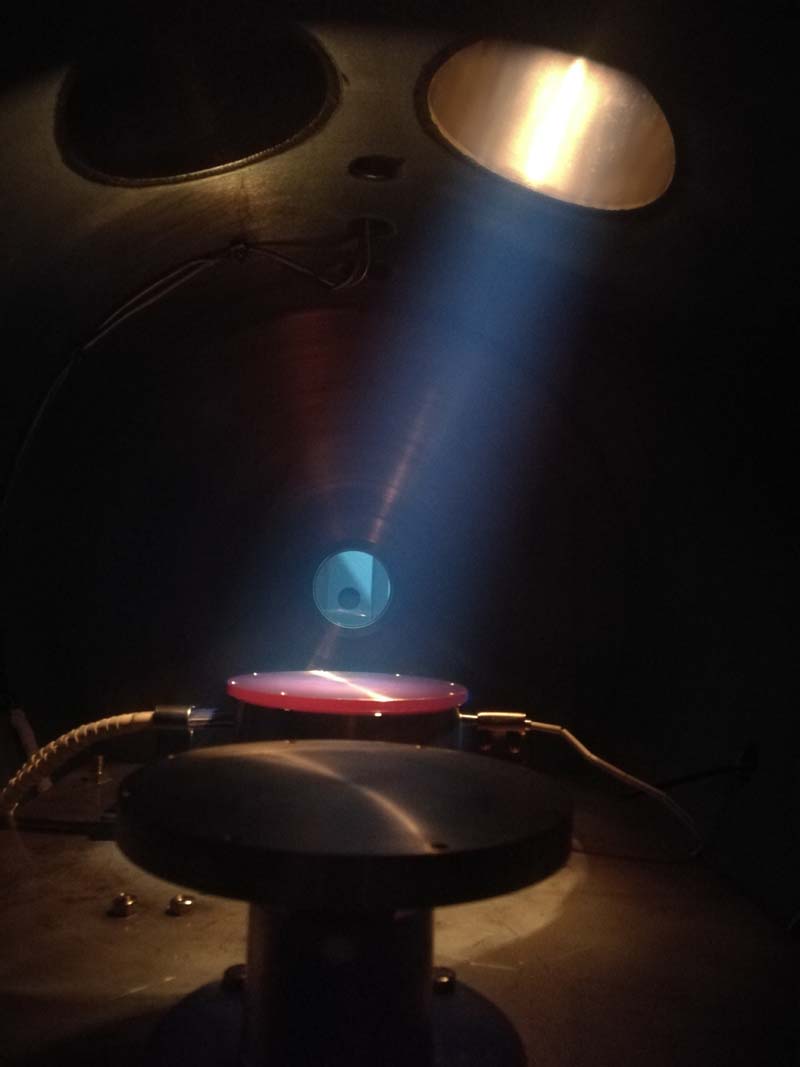

Dual Sources Ion Implanter

Advanced Dual-Source Ion Implantation System

Precision, Efficiency, and Scalability for High-Throughput Applications

Key Features & Technical Advantages:

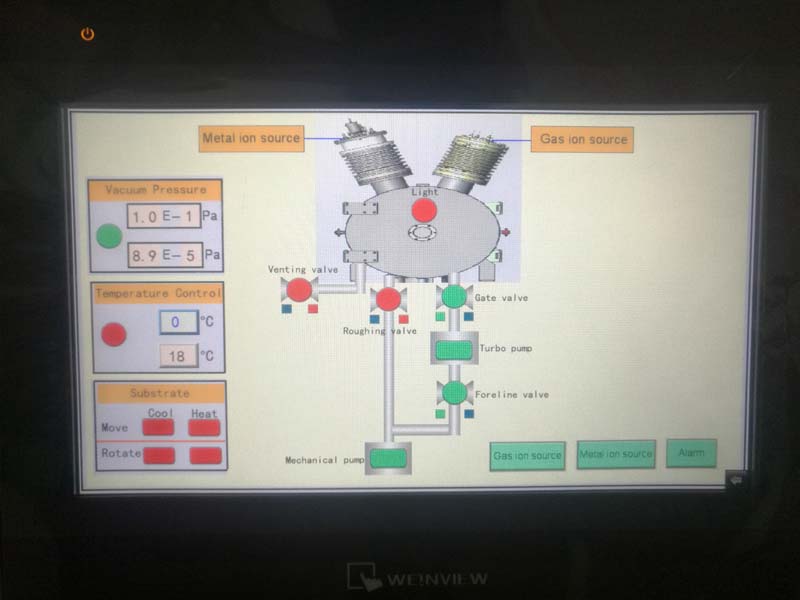

- Dual High-Energy Ion Source Configuration

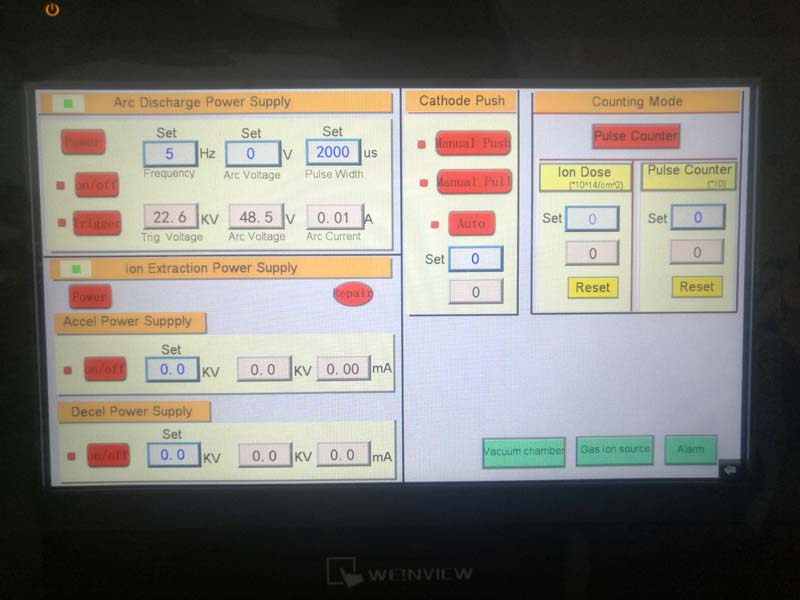

- Metal Ion Generation: Pulse-mode MEVVA (Metal Vapor Vacuum Arc) ion source enables stable, high-purity metallic ion beams for robust implantation processes.

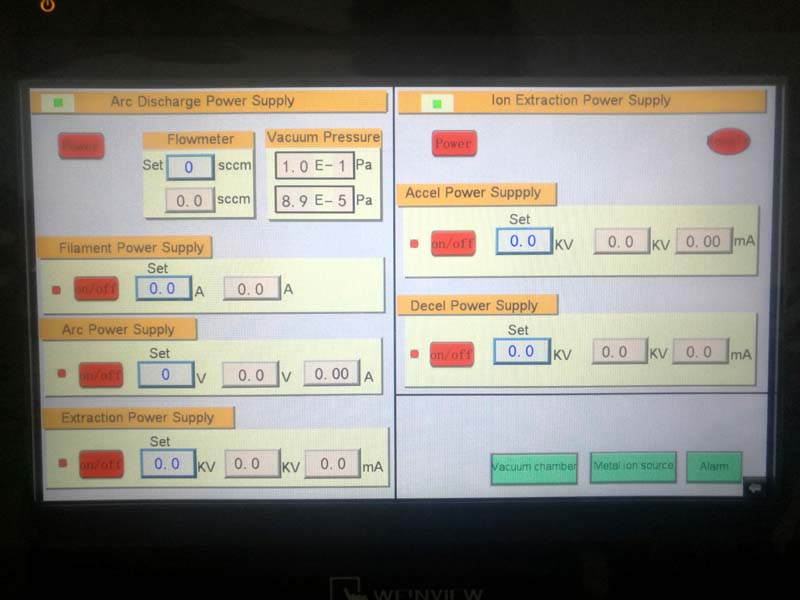

- Gas Ion Generation: Filament discharge gas ion source delivers consistent gaseous ion production with adjustable ionization parameters.

- Acceleration Flexibility: Ions are accelerated via a high-voltage grid system (10-50 kV), ensuring precise energy control for tailored implantation depths and material compatibility.

- High-Fluence, Large-Area Implantation Capability

- Broad Beam Technology: Standard F100mm uniform ion beam achieves high ion fluence (up to 10¹⁷ atoms/cm² in <1 hour), drastically reducing process time for industrial-scale throughput.

- Scalable Solutions: Optional F150mm+ beam configurations support large-area substrates (e.g., 6-inch wafers), ideal for semiconductor and advanced materials manufacturing.

- Energy & Current Range:

- Implantation Energy: 10-50 keV (adjustable for material-specific penetration and doping profiles).

- Beam Current: 3-5+ mA, enabling high-dose implantation with exceptional uniformity and speed.

- Smart Automation & Process Control

- PLC-Driven Operation: Fully automated control via programmable logic controllers (PLC) ensures repeatability, safety, and minimal operator intervention.

- Intuitive Touchscreen Interface: User-friendly HMI (Human-Machine Interface) simplifies parameter adjustments, real-time monitoring, and process diagnostics.

- Precision Dose Management: Integrated dose controller guarantees +/-1% accuracy for critical applications, enhancing yield and material performance.

- Industrial-Grade Performance

- Ruggedized Design: Engineered for 24/7 operation in demanding environments, with minimal downtime and maintenance.

- Safety Compliance: Automated interlocks, vacuum integrity protocols, and fail-safe mechanisms align with global industrial safety standards.

Market Applications:

- Semiconductor doping (SiC, GaN, etc.)

- Surface modification for wear/corrosion resistance

- Optoelectronics and photovoltaic device fabrication

- R&D in advanced materials science

Competitive Advantages:

- Unmatched Throughput: Achieve high-concentration doping 5x faster than conventional systems.

- Process Versatility: Seamlessly switch between metallic/gaseous ions for multi-material workflows.

- Future-Proof Scalability: Modular design supports beam upgrades for emerging substrate sizes.

Download "SRIM Software" This is a very good free software to calculate the ion projected range and ion distribution in the materials.

For additional product information and pricing contact our specialists at sales@plasmatechnol.com.

Related Scientific Publications

1. K. Feng, X. Cai, Z. G. Li, and P. K. Chu, "Improved Corrosion Resistance of Stainless Steel 316L by Ti Ion Implantation", Materials Letters, vol. 68, no. 1, pp. 450 - 452 (2012).

2. K. Feng, T. Hu, X. Cai, Z. G. Li, and P. K. Chu, "Ex Situ and In Situ Evaluation of Carbon Ion-Implanted Stainless Steel Bipolar Plates in Polymer Electrolyte Membrane Fuel Cells", Journal of Power Sources, vol. 199, pp. 207 - 213 (2012).

3. Y. Zhao, G. S. Wu, H. B. Pan, K. W. K. Yeung, and P. K. Chu, "Formation and Electrochemical Behavior of Al and O Plasma-Implanted Biodegradable Mg-Y-RE Alloy", Materials Chemistry and Physics, vol. 132, no. 1, pp. 187 - 191 (2012).

4. K. Feng, G. S. Wu, T. Hu, Z. G. Li, X. Cai, and P. K. Chu, "Dual Ti and C Ion-Implanted Stainless Steel Bipolar Plates in Polymer Electrolyte Membrane Fuel Cells", Surface and Coatings Technology, vol. 206, no. 11 - 12, pp. 2914-2921 (2012).

5. R. Z. Xu, G. S. Wu, X. B. Yang, X. M. Zhang, Z. W. Wu, G. Y. Sun, G. Y. Li, and P. K. Chu, "Corrosion Behavior of Chromium and Oxygen Plasma-Modified Magnesium in Sulfate Solution and Simulated Body Fluid", Applied Surface Science, vol. 258, no. 20, pp. 8273 - 8278 (2012).

6. R. Z. Xu, X. B. Yang, K. W. Suen, G. S. Wu, P. H. Li, and P. K. Chu, "Improved Corrosion Resistance on Biodegradable Magnesium by Zinc and Aluminum Ion Implantation", Applied Surface Science, vol. 263, pp. 608 - 612 (2012).

7. Y. Zhao, G. S. Wu, J. Wu, Q. Y. Lu, J. Wu, R. Z. Xu, K. W. K. Yeung, and P. K. Chu, "Improved Surface Corrosion Resistance of WE43 Magnesium Alloy by Dual Titanium and Oxygen Ion Implantation", Thin Solid Films, vol. 529, pp. 407-411 (2013).

8. Y. Zhao, J. Mohammed Ibrahim, W. K. Li, G. S. Wu, Y. F. Zheng, K. W. K. Yeung, and P. K. Chu, "Enhanced Antimicrobial Properties, Biocompatibility, and Corrosion Resistance of Plasma-Modified Biodegradable Magnesium Alloys", Acta Biomaterialia, vol. 10, no. 1, pp. 544 - 556 (2014).

9. R. Z. Xu, X. B. Yang, P. H. Li, K. W. Suen, G. S. Wu, and P. K. Chu, "Eelectrochemical Properties and Corrosion Resistance of Carbon-Ion-Implanted Magnesium", Corrosion Science, vol. 82, pp. 173 - 179 (2014).

10. W. H. Jin, G. S. Wu, H. Q. Feng, W. H. Wang, X. M. Zhang, and P. K. Chu, "Improvement of Corrosion Resistance and Biocompatibility of Rare-Earth WE43 Magnesium Alloy by Neodymium Self-Ion Implantation", Corrosion Science, vol. 94, pp. 142 - 155 (2015).

11. W. H. Jin, G. S. Wu, A. Gao, H. Q. Feng, X. Peng, and P. K. Chu, "Hafnium-Implanted WE43 Magnesium Alloy for Enhanced Corrosion Protection and Biocompatibility", Surface and Coatings Technology, vol. 306, Part A, pp. 11 -15 (2016).

|